Post Key-points For Handling Dimethyl sulfoxide Storage and Stability

The aftercare services and handling measures are the most overlooked but critical aspects of manufacturing. Unfortunately, many industries lack the basic knowledge in this field and the services, which can result in rendering the time, money and effort useless. Having said that, let’s take a step towards understanding the requisite processes.

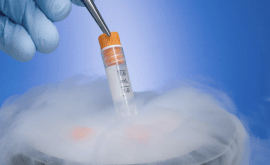

Dimethyl sulfoxide Storage

Subsequent research has indicated that storing DMSO at room temperature is safe after large-scale manufacturing.

It is fairly stable while placed in contact with varying heat.

Thus, it is denoted as thermally stable and can be heated up to a temperature point of 150 °C continuously for 24 hours without any noticeable degradation in its quality according to purity standards.

When the package is received, it may arrive in the solid state, unlike the regularly available liquid state. However, the state of matter can be changed by warming the product to room temperature without any deterioration in the product.

However, heating the product extensively leads to the decomposition of the original chemical compound into methyl mercaptan and bis methylthio methane, along with the release of pungent-smelling, poisonous gas.

Acids facilitate this breakdown, and the use of appropriate bases can observe the counter-effect.

While dimethyl sulfoxide is stable up to 100° Celsius when placed in alkaline, acid and neutral environments, the elimination of these can gear partial breakdown between 40 and 60°C resulting in observable alteration in physical parameters – viscosity, Density, Miscibility and Refractive Index.

Considering all these factors, storing DMSO in sterile, impermeable, light-resistant holders is recommended. It can be mixed with water or dried through a molecular sieve for long-term storage purposes.

It is ideal to go for glass containers and avoid the usage of plastic as much as possible.

Methods of Purification of Dimethyl sulfoxide shortage

The manufacturing process of dimethyl sulfoxide primarily depends on one key material, namely, Dimethyl sulfide.

By the end of it, the only contaminations accumulated is water with a small percentage of dimethyl sulfone. The Karl-Fischer test determines the water percentages in the final sample.

For small-scale purification, the sample is dried with Linde types 4A or 13X molecular sieve by extended exposure, which is later distilled under low pressures.

Alternative drying agents such as CaH2, CaO, BaO and CaSO4 can be used in case of unavailability to partially crystalline it.

On the other hand, voluminous purification calls for overnight standing of the mixture of freshly obtained alumina in its activated state.

Following this, it is refluxed and dried with CaO and CaH2 for about 4 hours and finally distilled at low pressure.

To speed up the process, it can be directly made to stand over a composition containing BaO, Alumina and CaSO4 and distilled over CaH2 using reduced pressure to obtain the final purified compound.

The temperature should be kept below 90°C throughout all the above-mentioned processes to eliminate the chances of a disproportionation reaction.

Since dimethyl sulfoxide has the potential to react

with certain substances to create an outburst, close attention must be paid to the water removal and purification process to avoid mishaps.

The Recovery Process from dimethyl sulfoxide Storage

Dimethyl sulfoxide recycling is an important step that needs to be considered for recovering the purified sample, which its unique properties can aid.

Dimethyl sulfoxide, an excellent solvent and easily soluble in water, benzene, and toluene, can segregate impurities, cutting costs.

Ether or reverse extraction can be used, followed by vacuum distillation to obtain pure-grade chemicals.

Once done with manufacturing, the above-mentioned processes need to be taken care of to increase the shell life of DMSO while not compromising product quality across sectors.